products

PRODUCTS SERIES

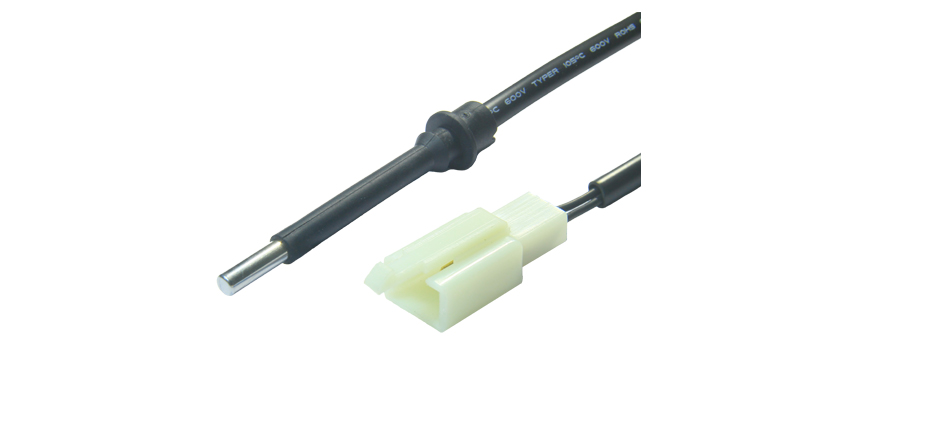

Temp sensor for car air conditioning

Name: Temperature sensor for automotive air conditioning(Room temperature)

■ Features

| Band: Veteng | Use: For temperature sensing(Room temperature) |

| Product model: VT0152XA161 | Product working temp range: - 40℃ ~ +125℃ |

Agency recognition: UL ROHS | NTC thermistor working temp. range: - 40℃ ~ +150℃ |

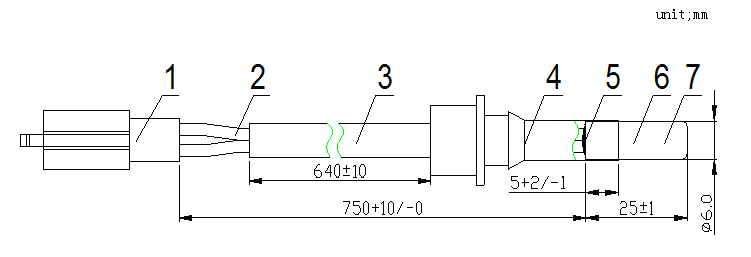

■ Product Drawing

■ Material List

| Item | Material | datasheet | Quantity |

| 6 | shell | Ф6.0X25 stainless steel shell (flat bottom) | 1PCS |

| 7 | NTC Thermistor | LSEC152X3820HT R0=4.852KΩ±5% B0/15=3820K±2% | 1PCS |

| 5 | Epoxy resin | G-108L: GU-01L: G-008X Black | / |

| 3 | Tube | Φ6.0*7.0 600V PVC Black tube | 1 PCS |

| 4 | Tube | Φ8.0X18X80 black rubber tube | 1 PCS |

| 2 | wire | UL3266 22AWG 2C TS 300V 125℃ Black | 1PCS |

| 1 | Terminal | DJ611-2.8X0.5A brass | 2PCS |

| Housing | DJ7021A-2.8-11 beige | 1PCS |

● The Shell, component, wire, connector, and their color, size, shape, and processing methods, all can

be customized according to your design

● The special shape of the shell and component, we can cooperate with the design and manufacture of

new molds

● If you need some samples, please contact us

■ Electrical Characteristic

| NO. | Item | Symbol | Test Conditions | Min. | Nor. | Max. | Unit |

| 1 | Resistance at 0℃ | R0 | Ta=0℃±0.05℃ PT≦0.1mW | 4.609 | 4.852 | 5.095 | KΩ |

| 2 | Resistance at 15℃ | R15 | Ta=15℃±0.05℃ PT≦0.1mW | / | 2.351 | / | KΩ |

| 3 | B Value | B0/15 | 5247.212* LnK | 3743.6 | 3820.0 | 3896.4 | K |

| 4 | Thermal Dissipation Constant | δ | Ta=25℃(in air) | / | 4.0 | / | m W/℃ |

| 5 | Response Time-In liquid | τ | Ta=25±0.5℃ | / | / | 5.0 | Sec |

| 6 | Hi-Pot Test | / | DC1800V 60Sec | / | / | 1.0 | mA |

| 7 | Insulation test | / | DC500V 60Sec | 100 | / | / | MΩ |

● The resistance, B value and other parameters can be selected as your requirements

■ Mechanical Tests

| NO. | Item | Pass Criteria | Test Conditions |

|---|---|---|---|

| 1 | Pull Test | Not loose, no deformation | 1 Resin, at the wire bonding, apply 20N (about 2.0KG) for 1 minute 2 Between the terminals and the wires, apply 30N (about 5.0KG) for 1 minute |

| 2 | Drop Test | Appearance no obvious damage | At the height of 1 meters, the product falls freely and falls to the 10mm thick oak board, 3 times |

■ Reliability Tests

| NO. | Item | Pass Criteria | Test Conditions |

|---|---|---|---|

| 1 | High Temperature Storage | ⊿R/R25≤±3% ⊿B/B≤±3% No visible damage to appearance | 105±3℃,1000±24H,Apply DC5V, series 1KΩ fixed resistance,After the test, wait at normal temperature for 2 hours |

| 2 | Low Temperature Storage | -40±3℃,1000±24H,Apply DC5V, series 1KΩ fixed resistance,After the test, wait at normal temperature for 2 hours | |

| 3 | Constant temperature and humidity test | 40±2℃,90%~95% RH,100H±24H After the test, wait at normal temperature for 2 hours | |

| 4 | Temperature impact test(in air) | 105℃×10min→25℃×20Sec→40℃×10min→25℃×20Sec,Cycle 1800 times After the test, wait at normal temperature for 2 hours | |

| 5 | Boiled test | 90±3℃,1000±24h,Apply DC5V,series 1KΩ fixed resistance,After the test, wait at normal temperature for 2 hours | |

| 6 | Salt spray test | 5% brine, 35 ℃ ± 1 ℃, 96H, the surface corrosion area should not exceed 5% of the surface area | |

| 7 | Anti-collision test | The sensor is tilted by 60 degrees, free fall, the sensor is collided with a minimum of 25KG steel plate | |

| 8 | Overcurrent test | 105 ± 3 ℃, apply 5min constant current, After 24h test,wait at normal temperature for 2 hours | |

| 9 | Vibration test | Frequency: 10 ~ 55Hz, amplitude: 2.5mm ,direction: X, Y, Z, each 6 hours |

■ Storage Conditions

1 Ambicnt Temperature: -10℃~+40℃

2 Relative Humidity: ≦75%RH

3 Keep away from corrosive atmosphere and sunlight

4 Period of Storage: 1 year

■ Product Application Conditions

1 Maximum service temperature and maximum power in application should not exceeds specification listed in Product Specification;

2 Much be handled with care when moving and installing the product;

3 Product should not be used when deformed or rusty casing is observed on product;

4 Product should not be used when broken housing ,or excessive deformation on housing is observed;

5 Avoid excessive temperature fluctuation when operating the product in its operational temperature range;

6 Do not apply excessive shock and vibration on product;

7 Do not pull or bend the lead wire excessively;

8 Do not use in any ambient with corrosiven gas (CO2,NH3,Sox,Nox);

Do not use in any ambient with electrolytic solution with brine,acid,alkaline and organic

9 Do not use in environment with water.high moisture,and high corrosive solution;

10 Current throught NTC element will cause self-heating,and may affect the measurement;

11 This product belongs to surface appressed type sensor temperature, when using, need to make bottom plane fully and heating;

● We are so happy to answer any questions. send a message or E-mail to us. We will respond as soon as possible.

● Ordering process:Confirm the product and datasheet → Send samples → Confirm samples and quotes → Test passed → Order+ payment → Manufacture+payment → Deliver

● Because the temperature sensors are custom products, can only be ordered in bulk and not retail

● For other NTC temperature sensors not listed on this website, please contact us, Yes, direct procurement from China is so easy

Copyright © Dongguan Shine Electronic Technique Co.,Ltd. All Rights Reseved.Site Index Product Index

Technical Support: 3xh1 web